The first part of the project was levelling the ground and then bringing in large plant to drill, reinforce and cast concrete 6m deep contiguous piling along the side of the road to ensure it had support. Once the piles were cast, they were joined by a “pile cap beam” which consists of reinforcing and concrete that joins the heads of all piles.

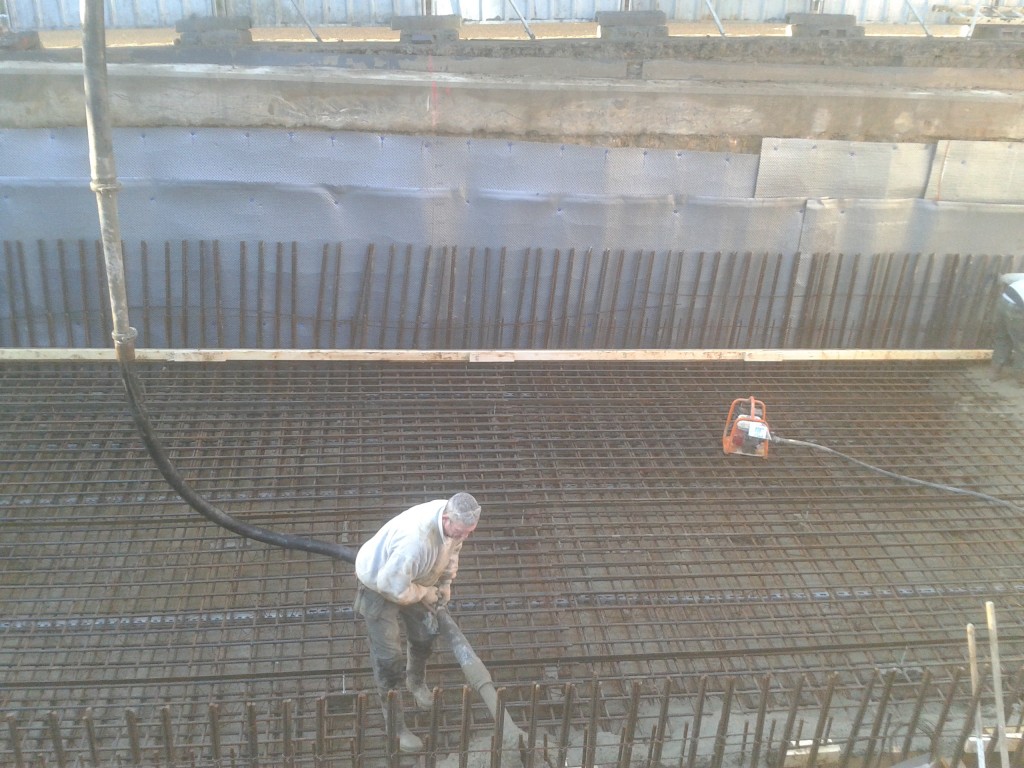

Once complete the excavation could be dug to formation level and the main concrete slab could be cast.

The basement walls were then created using temporary timber shuttering and mass filled reinforced concrete, separated and built in two halves.

Waterproofing for the project was comprised of two systems to comply with 3rd party warranty requirements.

- External drainage channels linked to permanent external sump & pumping station to reduce external water pressure

- Internal cavity drainage membrane, linked to a sump & pumping station